CABLE MESH INSTALLATION DATA

For more information about installing, cutting or connecting the length of Qinkai, we have collected useful guidelines from branches, which can also be found in our catalog. For a more detailed comparison between cable network and cable tray system, please see the cable tray introduction here.

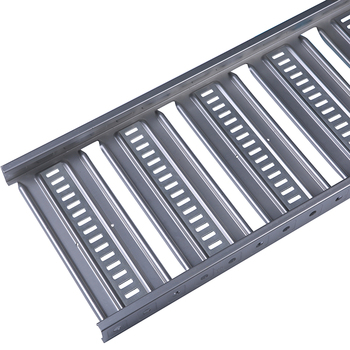

QINKAI T3 LADDER TYPE CABLE TRAY

T3 Ladder Tray System is designed for trapeze supported or surface mounted cable management and is ideally suited to small, medium and large size cables such as TPS, data comms, Mains & sub mains.

T3 offers full integration saving the installer from having to carrying two ranges of accessories.

Load and Deflection data is derivd from tests performed in a NATAcertified testing environment in accordance to NEMA VE1-2009STANDARDS.

ALL Ladders exceed the class designation that has been applied to the product.

Load data is based on single spans resulting in worst case scenaril.Deflections listed in our table are based on continuous spans,single span installation will result in increased deflection,for single spans multiply the corresponding deflection by 2.5 For further information regarding Nema VE 1-2009 Standards Safety Factor 1.5 over collapse load

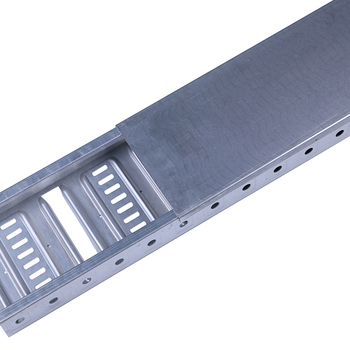

| Ordering Code | Cable Laying Width W (mm) | Cable Laying Depth (mm) | Overall Width (mm) | Side Wall Height (mm) |

| T3150 | 150 | 43 | 168 | 50 |

| T3300 | 300 | 43 | 318 | 50 |

| T3450 | 450 | 43 | 468 | 50 |

| T3600 | 600 | 43 | 618 | 50 |

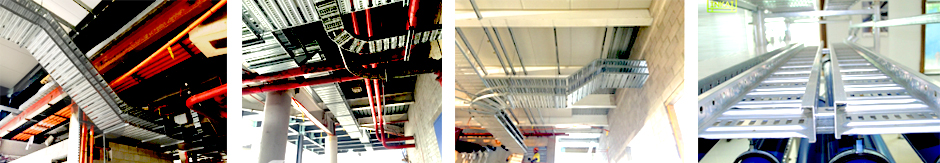

SCOPE OF APPLICATION OF TROUGH BRIDGE AND LADDER BRIDGE

TROUGH BRIDGE

The trough type cable tray is a kind of fully enclosed cable tray that belongs to the closed type.

The trough bridge is suitable for laying computer cables, communication cables, thermocouple cables and other control cables of highly sensitive systems.

The trough bridge has a good effect on the shielding interference of the control cable and the protection of the cable in the heavily corrosive environment.

The slotted bridge generally has no openings, so it is poor in heat dissipation, while the bottom of the slot of the ladder bridge has many waist-shaped holes, and the heat dissipation performance is relatively better.

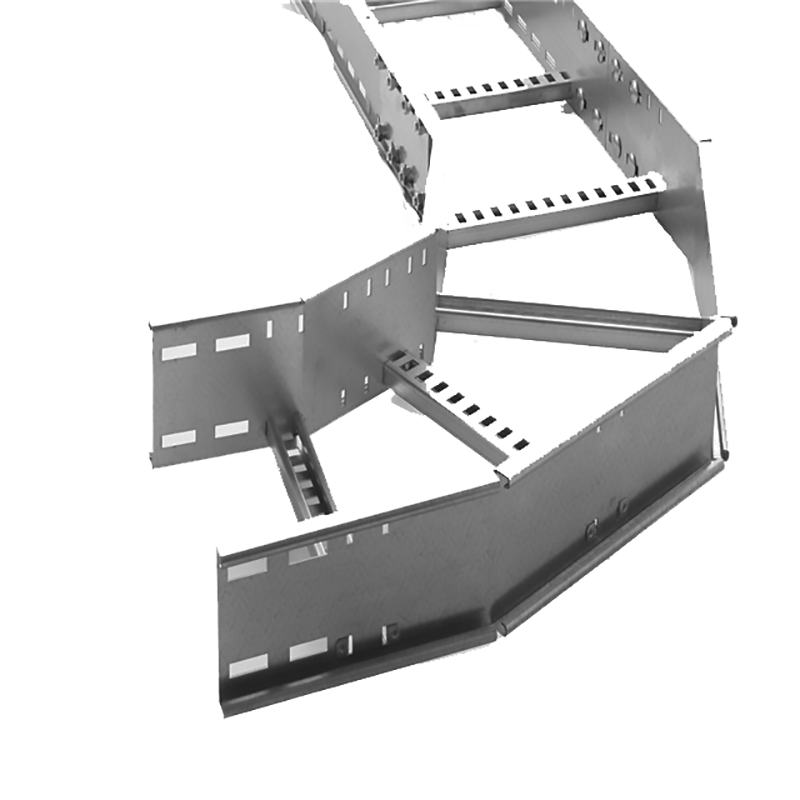

SECOND, THE LADDER BRIDGE

The ladder type bridge is a new type improved by the company based on relevant domestic and foreign materials and similar products. The ladder type bridge has the advantages of light weight, low cost, unique shape, convenient installation, good heat dissipation and good air permeability.

The ladder type bridge is suitable for the laying of cables with larger diameters in general, especially for the laying of high and low voltage power cables.

The ladder-type bridge is equipped with a protective cover, which can be specified when ordering when a protective cover is required.

For the general construction environment and according to the design drawings, the ladder-type bridge is specially used for laying large-diameter cables, and the trough-type bridge is also the most commonly used model. The 360° fully-sealed bridge has the main function of shielding interference and corrosion resistance.

The shape of the stepped bridge is like a ladder (H). The bottom of the ladder is like a staircase, and there are baffles on the side. The dusty place uses a ladder, which will not accumulate dust.

CABLE LADDER

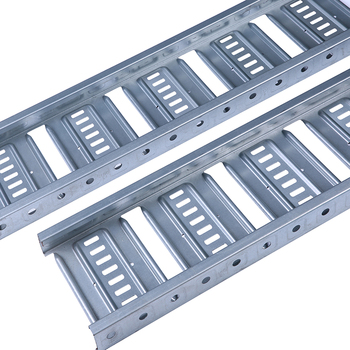

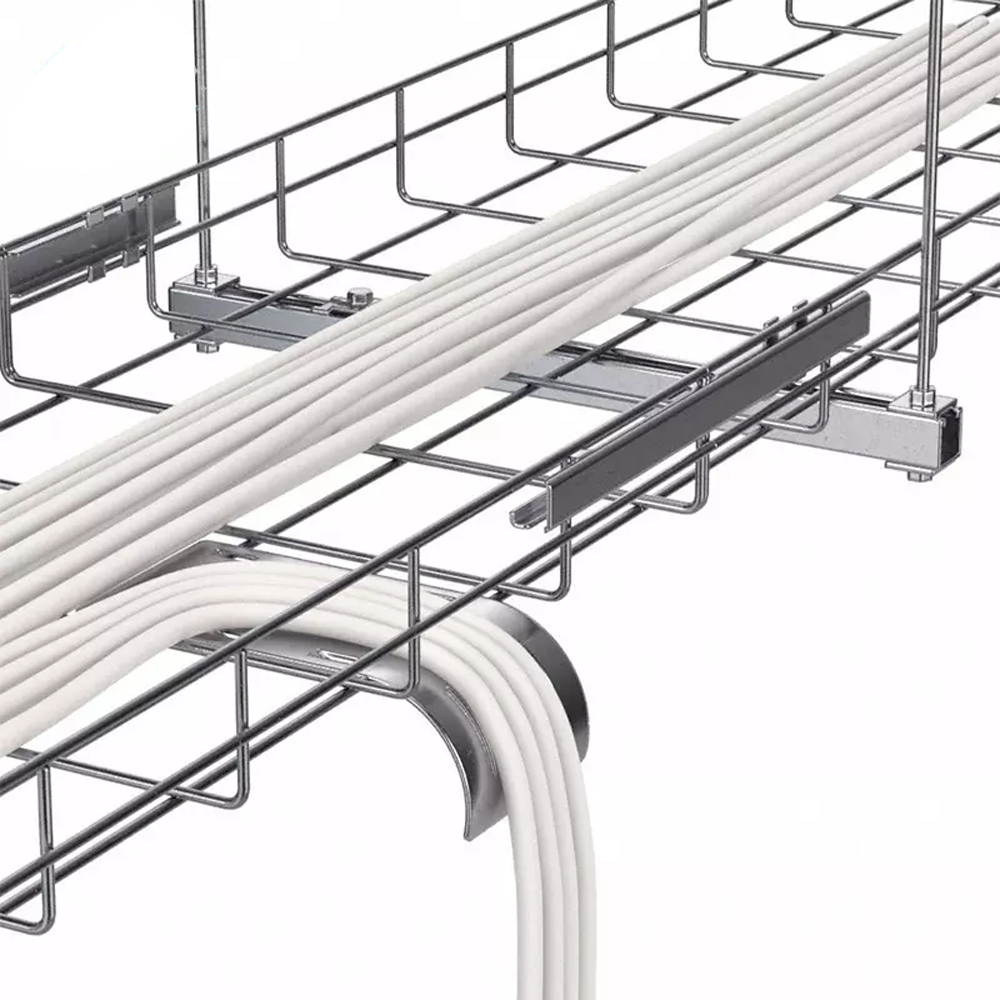

Qinkai Cable Ladder is an economical wire management system designed to support and protect wires and cables. Cable ladders can be used for a variety of indoor and outdoor applications.

Ladder type cable trays are designed to carry heavier cable loads than standard perforated cable trays. This product group is easy to apply vertically. On the other hand, the form of cable ladder provides nature.

The standard finish of Qinkai cable ladder is as follows, which can be customized according to different widths and load depths. It is suitable for various applications, including main service entrance, main power feeder, branch line, instrument and communication cable. Combines ruggedness and ladders, but provides additional support to ensure that cables are strong and uniform Prevent dust, water or falling debris Adequate ventilation to ensure that the heat generated in the cable conductor is effectively dissipated without moisture accumulation Easy access to cables from top or bottom Maximum protection against electromagnetic or radio frequency interference Protect and shield sensitive circuits

QINKAI CABLE LADDER PARAMETER

| Model No. | Qinkai cable ladder | Width | 50mm-1200mm |

| Side Rail Height | 25mm -300mm or According to Requirements | Length | 1m-6m or According to Requirements |

| Thickness | 0.8mm-3mm According to Requirements | Materials | Carbon Steel, Aluminum,Stainless Steel,Fiber glass |

| Surface Finished | Pre-Gal,Electro-Gal,HDG,Power Coated,Paint,matt,anodizing,satt,polished or other surface you need | Max.Working Load | 100-800kgs, According to Size |

| MOQ | for Standard Size, Availablefor All Quantity | Supply Ability | 250 000 meters Per Month |

| Lead Time | 10-60 Days according to quantities | Specification | according to your needs |

| Sample | avialable | Transport Package | bulk,carton,pallet,wooden boxes,According to Requirements |

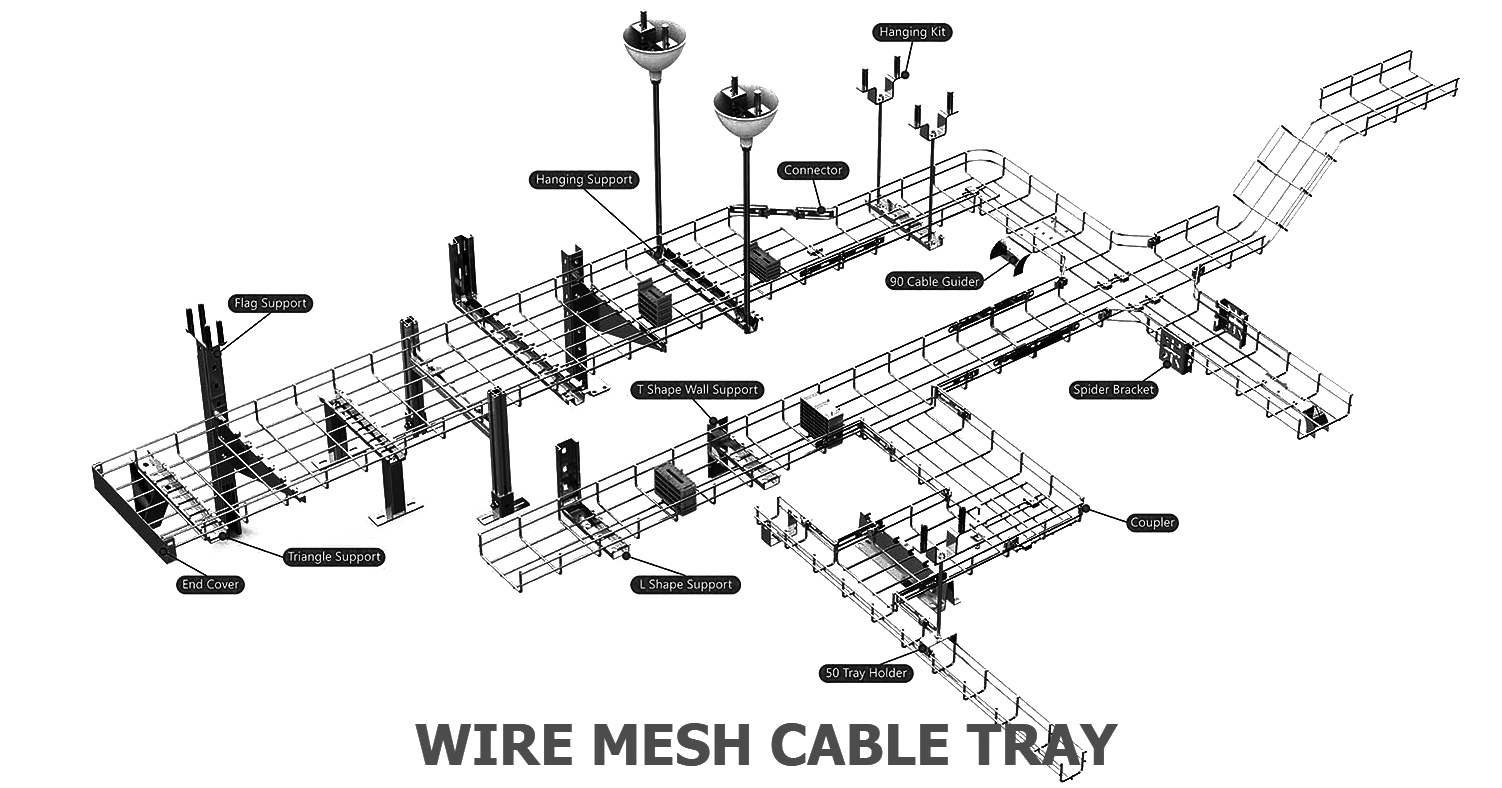

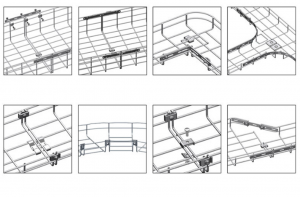

WIRE MESH CABLE TRAY

T3 Ladder Tray System is designed for trapeze supported or surface mounted cable management and is ideally suited to small, medium and large size cables such as TPS, data comms, Mains & sub mains.

T3 offers full integration saving the installer from having to carrying two ranges of accessories.

Load and Deflection data is derivd from tests performed in a NATAcertified testing environment in accordance to NEMA VE1-2009STANDARDS.

ALL Ladders exceed the class designation that has been applied to the product.

Load data is based on single spans resulting in worst case scenaril.Deflections listed in our table are based on continuous spans,single span installation will result in increased deflection,for single spans multiply the corresponding deflection by 2.5 For further information regarding Nema VE 1-2009 Standards Safety Factor 1.5 over collapse load

CANTILEVER BRACKETS

150mm through to 900mm long cantilever using QK1000 41x41mm channel/strut.

Cantilever Brackets are manufactured to complement the range of cable support systems.

Fully galvanised after fabrication to provide heavy duty protection in most conditions.

Can also be manufactured in stainless steel grade 316 for use in extremely corrosive environments.

Fibreglass brackets available upon request.

Advangtages of Qinkai Channel Cantilever Bracket

1. To make construction easier and more convenient, saving time and labor cost

2. We do OEM for all kinds of steel brackets according to clinets' design.

3. Different kinds of fittings can set up many different combinations

4. Great concentrate Loading capacity

5, Brackets are manufactured from Q235 steel with galvanized finish or epoxy coating. Wall thickness is 2.5mm. Wall thickness can be 2.0mm and 1.5mm for light hanging system, for beam load capacity, use 80% and 60% of appropriate load chart separately.

6, Holes or slots are available on base plate on orders.

|

With |

Height |

Length |

Thickness |

|

27mm |

18mm |

200mm-600mm |

1.25mm |

|

28mm |

30mm |

200mm-900mm |

1.75mm |

|

38mm |

40mm |

200mm-950mm |

2.0 mm |

|

41mm |

41mm |

300mm-750mm |

2.5 mm |

|

41mm |

62mm |

500mm-900mm |

2.5 mm |

RIBBED SLOTTED CHANNEL WITH METAL STAINLESS STEEL ALUMNIUM ALLOY

C Channels are mainly used to mount, brace, support and connect lightweight structural loads in structures. These include pipes, electrical and data wires, mechanical systems such as ventilation and air conditioning, solar panel mounting system.

It is also used for other applications that require a strong framework, such as equipment racks, workbenches, shelving systems etc.

Strut channel provides light structural support for wiring, plumbing, or mechanical components. It has inward-facing lips for mounting nuts, braces, or connecting angles to join lengths of strut channels together. It is also used to connect pipes, wire, threaded rods, or bolts to walls. Most strut channel has slots in the base to facilitate interconnection or to fasten the strut channel to building structures. Strut channel is easy to connect and modify, and different channel styles can be mixed and matched. It’s commonly used in the electrical and construction industries. Strut channel can be used to create a permanent structure that supports wiring around a property, or it can temporarily store different types of machinery and wires for short-term projects.

| Product Name | Slotted Strut Channel ( C Channel, Slotted Channel) |

| Material | Q195/Q235/SS304/SS316/Aluminum |

| Thickness | 1.0mm/1.2mm/1.5mm/1.9mm/2.0mm/2.5mm/2.7mm12GA/14GA/16GA/0.079''/0.098'' |

| Cross Section | 41*21,/41*41 /41*62/41*82mm with slotted or plain1-5/8'' x 1-5/8'' 1-5/8'' x 13/16'' |

| Length | 3m/6m/customized10ft/19ft/customized |

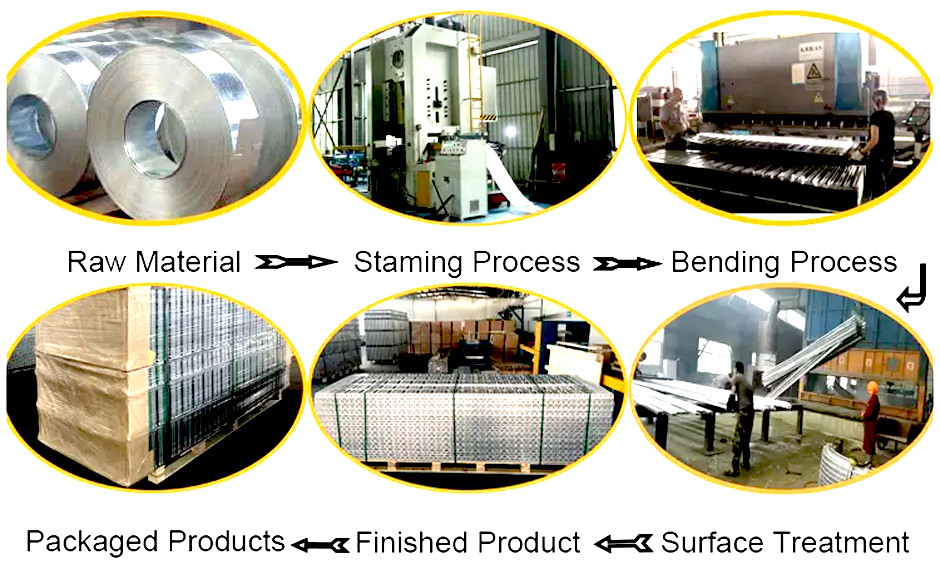

OUR TEAM

OUR CERTIFICATE