◉ Recently, friends often ask me: how much force can ordinary cold-formed C channel withstand? How to use is the safest? If it is not safe enough and what is the solution?

◉ The above questions in the safety calculation can actually be seen as a problem: how to rationally use C channel in order to make the project both safe and reliable?

I first from the C channel structure to explain:

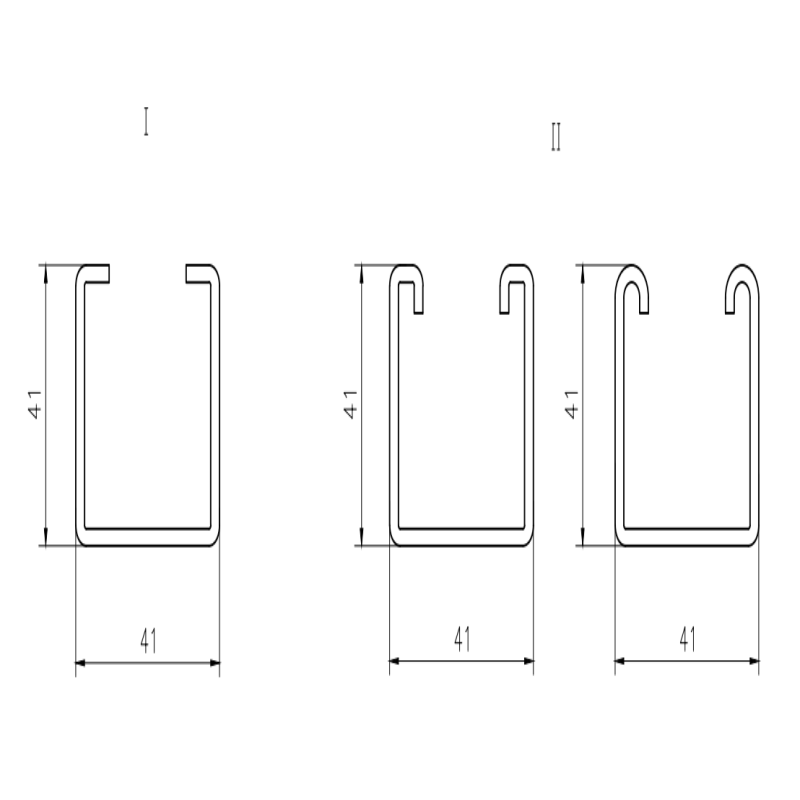

◉ First, C channel steel structure classification, see the following chart:

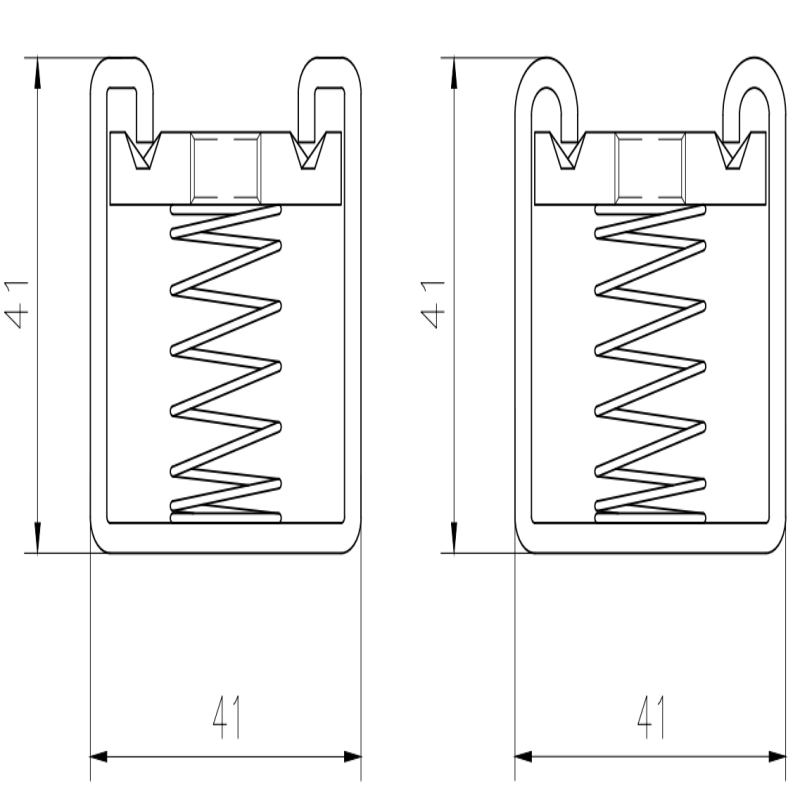

◉ See, it’s the snap spring nut. The purpose of this hook structure is obvious, as it makes it easy to turn the open groove of the section into a convenient structure for mounting spare parts. Most of the profile accessories and some components that need to be mounted can be mounted through the threaded holes of this spring nut.

◉ Thus, we can see that there is a big difference between the roles of Type I and Type II steel sections. Type Ⅱ is able to bear more knots structural needs, so most of my friends who are responsible for engineering installations choose Type II.

◉ Then Ⅱ why there will be two kinds of opening look? This point has to do with the earlier industry standardization of norms, the early C channel for the opening hook structure did not do a detailed definition, made into a rounded corner than to do into a square corner to save raw material costs, and the strength of the difference is not great, so there will be Ⅱ type of the two hook structure.

◉ Second, strength calculation comparison.

◉ In our industry, there have been many controversies about the strength of square corner and rounded corner C channel. So let’s calculate the strength of the two types of modeling C channel is how much?

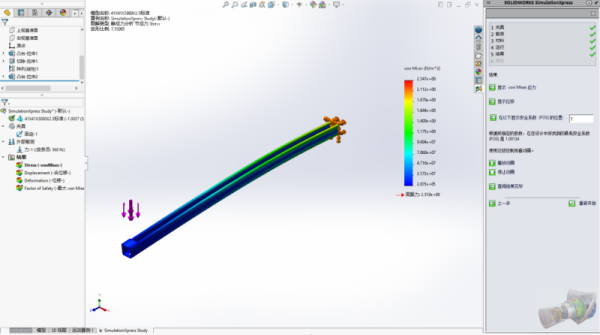

◉ First of all, set the same conditions, two types of steel are set to 1 meter long, cross-section size of 41X41X2.5, the same material for the Q235B. one end of the fixed, the other end of the force. Use linear element analysis to calculate the maximum load bearing, the results are shown below:

◉ Square corner section can withstand a force of 568N

◉ From the above results, the two types of steel can withstand such conditions of the maximum load difference of less than 0.4%, which can be concluded that the strength of rounded corners and square corners of the difference is not significant.

◉ Third, the use of examples to prove.

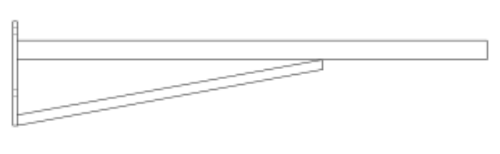

◉ The above computer calculation comparison fully explains the two structure C channel strength is very different, then from the force size, even if it is a steel channel, in such an unreasonable force situation, can withstand the force is only 566N ≈ 56KG. want to be stronger and more reliable way of bearing, it is necessary to optimize the force structure of the profile, such as the above situation, you can make this force into the structure that we need:

◉ This is the structure of our common bracket arm, when the cantilever exceeds a certain length, we can’t get a larger load on this profile, we can only add a diagonal support underneath to form a solid triangular structure. Then this will increase the load bearing by 600% to meet its usage requirement.

◉ To summarize the above, the answer I can give to my friend is: Before you need to know the maximum load of C channel, please put forward the maximum load and installation space required for the working condition. In this way, I can give certain technical support in accordance with the needs of the working conditions.

→ For all products,services and up to date information,please contact us.

Post time: Sep-20-2024