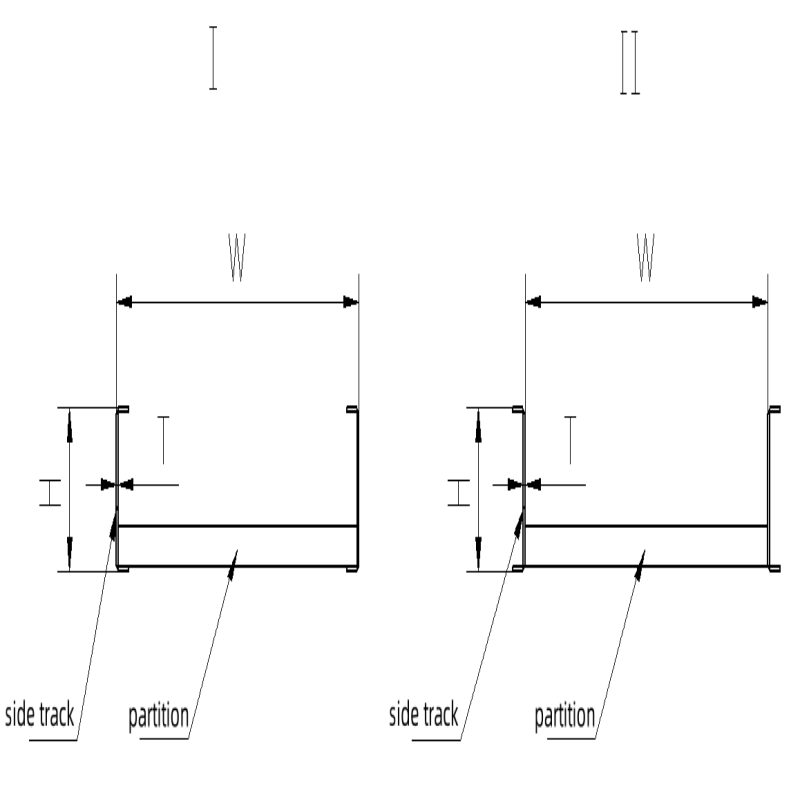

◉ Cable ladder rack. As the name suggests, it is the bridge that supports cables or wires, which is also called ladder rack because its shape is similar to a ladder. Ladder rack has a simple structure, strong load-bearing capacity, a large range of applications, and easy to install and easy to operate. In addition to supporting cables, ladder racks can also be used to support pipelines, such as fire pipelines, heating pipelines, natural gas pipelines, chemical raw material pipelines and so on. Different applications correspond to different product models. And each region or country according to the local needs of the external environment have developed different product standards, so a variety of product models called a variety of models. But the general direction of the main structure and appearance is about the same, can be divided into two main structures, as shown below:

◉ As you can see from the picture above, a typical ladder frame is made up of side rails and crosspieces. Its main dimensions are H and W, or height and width. These two dimensions determine the range of use of this product; the larger the H value, the larger the diameter of the cable that can be carried; the larger the W value, the larger the number of cables that can be carried. And the difference between Type Ⅰ and Type Ⅱ in the above picture is the different installation methods and different appearance. According to the customer’s demand, the main concern of the customer is the value of H and W, and the thickness of the material T, because these values are directly related to the strength and cost of the product. The length of the product is not the main problem, because the length of the project with the use of demand-related, let’s say: the project needs a total of 30,000 meters of products, the length of 3 meters 1, then we need to produce more than 10,000. Assuming that the customer feels 3 meters too long to install, or not convenient to load the cabinet, need to be changed to 2.8 meters a, then for us just the number of production into 10,715 or more, so that ordinary 20-foot container container can be loaded with more than two layers, there are some affluence of small space to install accessories. The production cost will have a little change, because the quantity increases, the corresponding number of accessories will also increase, the customer also need to increase the procurement cost of accessories. However, compared to this, the transportation costs are significantly lower, and this overall cost may be reduced slightly.

◉ The following table shows the corresponding values of H and W for ladder frames:

|

W\H |

50 |

80 |

100 |

125 |

150 |

200 |

250 |

300 |

|

150 |

● |

● |

● |

— |

— |

— |

— |

— |

|

200 |

● |

● |

● |

● |

— |

— |

— |

— |

|

300 |

● |

● |

● |

● |

● |

● |

● |

● |

|

400 |

● |

● |

● |

● |

● |

● |

● |

● |

|

450 |

● |

● |

● |

● |

● |

● |

● |

● |

|

600 |

● |

● |

● |

● |

● |

● |

● |

● |

|

900 |

— |

— |

● |

● |

● |

● |

● |

● |

◉ According to the analysis of the use of the product needs, when the value of H and W increases, the installation space inside the ladder rack will be larger. Generally speaking, the wires inside the ladder rack can be directly filled. It is necessary to leave enough space between each strand to facilitate heat dissipation as well as to minimize mutual influence. Most of our customers have made calculations and analyses before choosing the ladder racks, so as to confirm the choice of ladder rack models. However, we do not exclude that some customers do not know it very well, and will ask us some rules or methods in the selection. Therefore, customers need to pay attention to the following points for ladder rack selection:

1, installation space. Installation space directly restricts the upper limit of the product model selection, can not exceed the customer’s installation space.

2, environmental requirements. The product environment determines the product to the pipeline to leave the size of the cooling space and appearance requirements. The same also determines the choice of product model.

3, pipe cross-section. Pipe cross-section is a direct decision to choose the lower limit of the product model. Can not be smaller than the size of the pipe cross-section.

Understand the above three requirements. Can confirm the final size and shape of the product.

Post time: Aug-05-2024