T-type bridge generally refers to the ladder bridge, that is, the ladder bridge, and the ordinary bridge generally refers to the trough bridge, that is, the tray bridge without holes. Bridge structure is divided into trough type, tray type, ladder type and network format, etc., there are many bridge specifications, commonly used specifications are 100*50mm, 200*100mm, etc. Relevant knowledge points are summarized as follows:

When compiling the lifting list of ladder cable bridge hanger, fill in: name + height H+ cross arm length L, for example: through wire double pull hanger, specification H=2000mm,L=360mm (through wire hanger default cross arm length = slot width +60mm). The laying process of ladder cable bridge includes planning layout, bridge material inspection, support and hanger selection and processing, hole reservation, elastic wire positioning, horizontal bridge laying, vertical bridge laying, outdoor bridge laying, bridge connecting with boxes and cabinets, equipment, bridge grounding, bridge compensation and bridge marking.

The wall bracket of trough cable bridge is divided into horizontal and vertical along the wall. JY-TB102 brackets are selected for horizontal laying along the wall, and JY-TB105 brackets are selected for vertical laying along the wall. When horizontal installation of trough cable bridge, attention should be paid to avoid the surrounding buildings, to avoid the surrounding gas and liquid corrosion and solid physical damage, but also to ensure that the safety load is enough to avoid the occurrence of related accidents. There are also requirements and specifications in this aspect in the bridge standards.

3. Specifications of bridge frame

The commonly used small specifications of cable tray are 50*25mm, 60*25mm, 60*40mm, 60*50mm, 80*40mm, 80*50mm, 80*60mm, 100*50mm, 100*60mm, 100*80mm, etc. Sometimes the four outlet specifications of a cable bridge are different, which requires electrical engineers to make a detailed purchase list according to the requirements of the drawings, so that the bridge manufacturer can provide qualified cable bridge products for customers in time.

4. Bridge structure

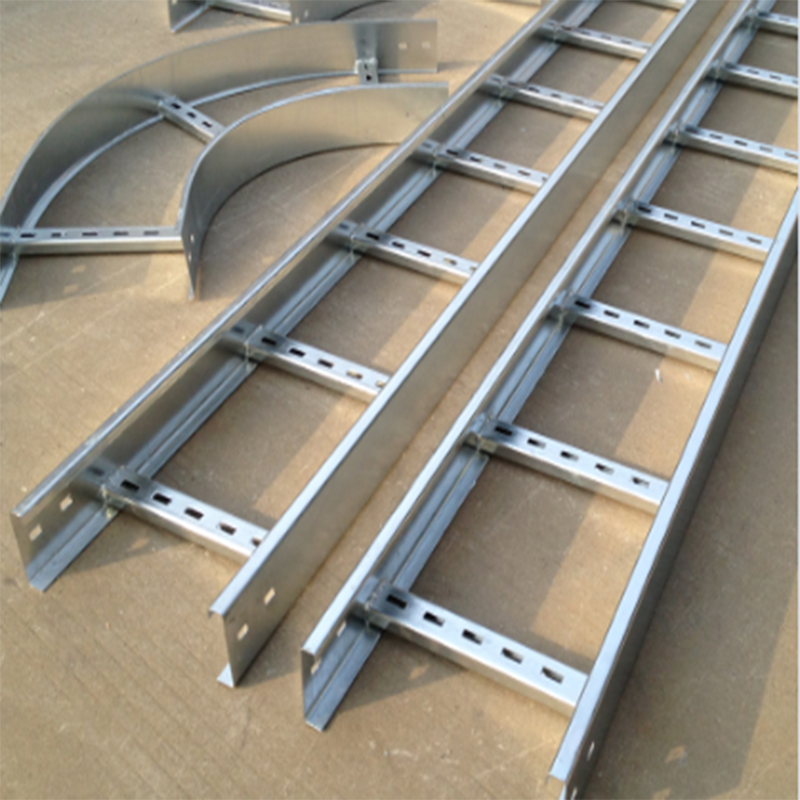

According to the structure type, the bridge can be divided into trough bridge, tray bridge, ladder bridge, mesh bridge and so on. Different structural types of bridge sealing and heat dissipation performance are not the same. Bracket and bracket arm is one of the main parts of cable bridge, with simple structure, high strength, low cost. If the cable bridge needs multi-layer heavy load lifting, it should be laid bilaterally.

5. Bridge material

When the tray and ladder laid by the cable bridge are non-galvanized materials, the two ends of the middle connecting plate of the bridge should adopt the cross-sectional area > =4 square meters of copper core jumper connection. Cable tray laying process includes planning layout, bridge material inspection, support and hanger selection and processing, hole reservation, elastic positioning, horizontal cable tray laying, vertical cable tray laying, outdoor cable tray laying, bridge and box cabinet, equipment connection, bridge grounding, bridge compensation and bridge marking.

If you are interested in this product, you can click the lower right corner, we will contact you as soon as possible.

Post time: Mar-24-2023