When it comes to structural steel components, U-channels and C-channels are two of the most commonly used profiles in construction and manufacturing. Both types of channels play an important role in a variety of applications, but they have different properties that make them suitable for different uses. Understanding the differences between U-channels and C-channels is essential for engineers, architects, and builders to choose the right material for their projects.

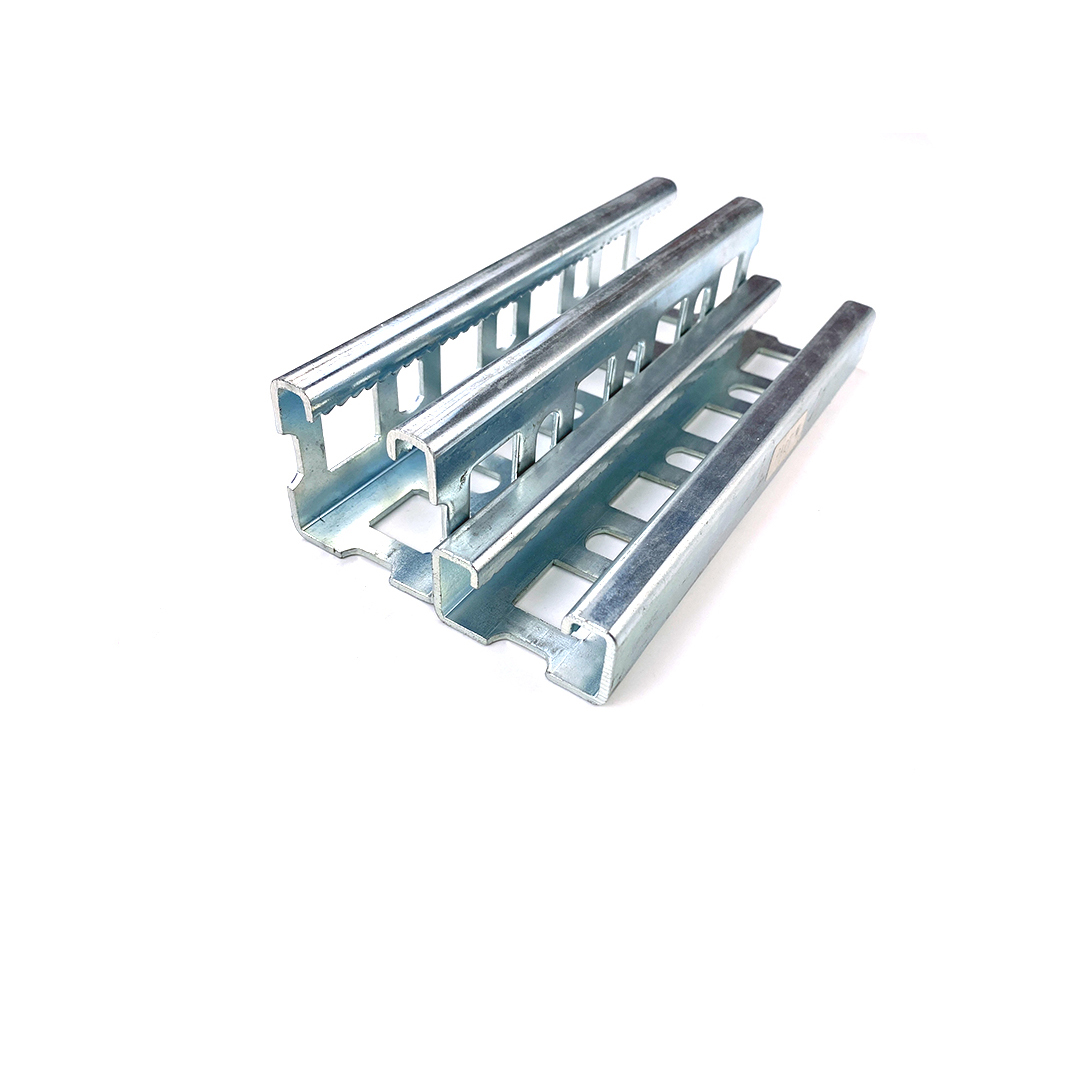

U-channels, commonly referred to as U-beams or U-sections, are characterized by their U-shaped cross-section. This design features two vertical legs connected by a horizontal base, resembling the letter “U”. The open sides of the U-channel can be easily connected to other materials, making it a versatile choice for a variety of applications.

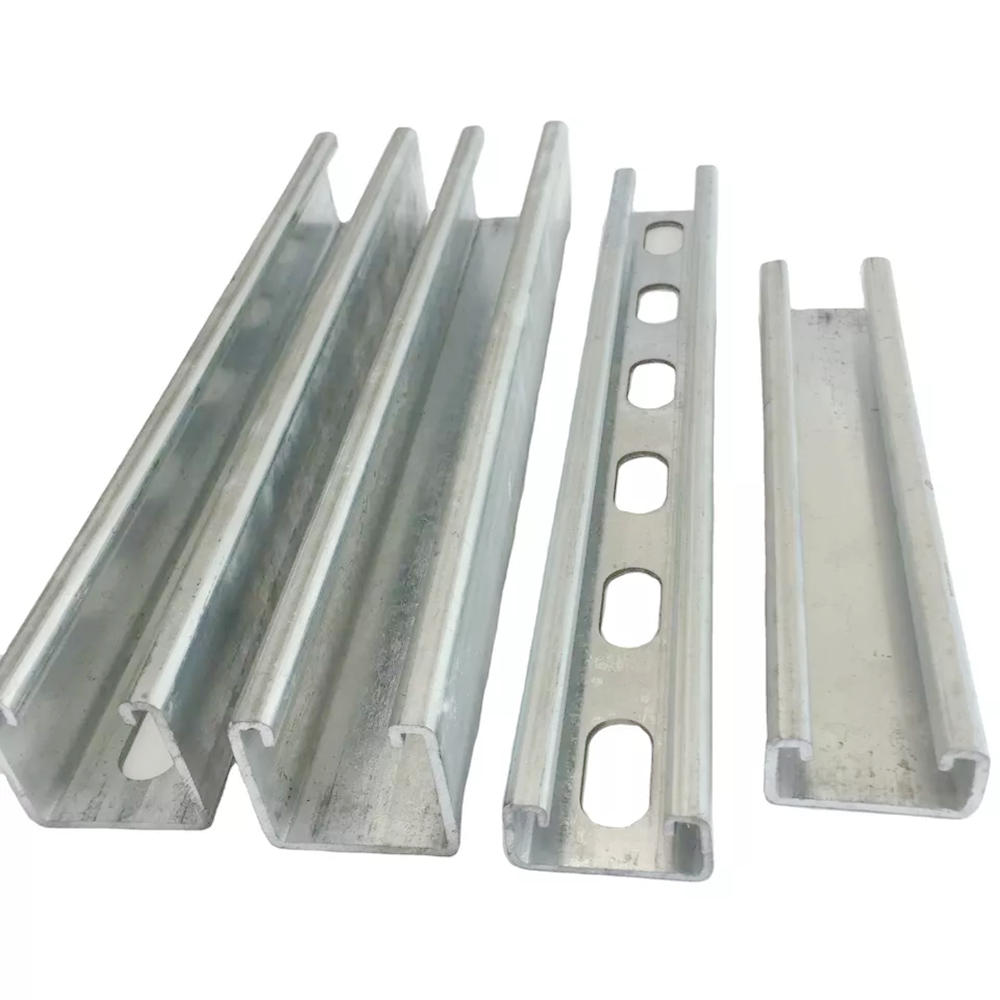

On the other hand, a C-channel (also called a C-beam or C-section) has a C-shaped cross-section. Similar to a U-channel, a C-channel consists of two vertical legs and a horizontal base, but the lip at the end of the legs is more pronounced, giving it a distinctive C-shape. This design provides additional strength and stability, making the C-channel a popular choice for structural applications.

One of the main differences between U-channels and C-channels is their strength and load-bearing capacity. Due to their design, C-channels are generally considered stronger than U-channels. The added lip at the end of the C-channel legs increases its resistance to bending and twisting, making it ideal for applications that require high load-bearing capacity.

While still strong, a U-channel may not provide the same level of support as a C-channel. However, its open design allows for greater flexibility in certain applications, such as when it needs to be welded or bolted to other components. The choice between the two often depends on the specific requirements of the project, including the loads it must support and the type of connection required.

U-channels and C-channels are widely used in construction, manufacturing, and a variety of industrial applications. U-channels are often used in applications that require a lightweight and versatile solution. Common uses include framing, bracing, and as supports for racking or equipment. Their open design easily integrates with other materials, making them a popular choice for custom fabrication.

C-channels are often used in structural applications such as building frames, bridges and heavy machinery due to their exceptional strength. They are able to withstand significant loads, making them ideal for use in environments where durability and stability are critical. Additionally, C-channels are often used to construct railings, brackets and other structural elements that require a strong frame.

In summary, while both U-channels and C-channels play important roles in construction and fabrication, they have distinct differences and are suited for different applications. U-channels are ideal for lightweight structures and custom projects due to their versatility and ease of connection. In contrast, C-channels are preferred for heavier applications due to their superior strength and load-bearing capacity. Understanding these differences is essential to selecting the right type of channel for your specific needs, ensuring your project is successful and safe.

→ For all products,services and up to date information,please contact us.

Post time: Feb-08-2025