Insimbi ehlukanisweinsimbi yesiteshiIngabe izinto zokwakha ezithandwayo neziguquguqukayo ezisetshenziswa ezinhlobonhlobo ezahlukahlukene zokwakha namaphrojekthi wokwakha. Isetshenziswa kakhulu ezinhlakeni zensimbi ezinjengezakhiwo, amabhuloho nezindawo zezimboni ngenxa yamandla ayo, ukuqina nokuvumelana nezimo. Kodwa-ke, lapho ukhetha isiteshi esilungiselelwe esifanele sephrojekthi yakho, kubalulekile ukubheka izinto ezahlukahlukene kanye nezakhiwo zazo ukuqinisekisa ukuthi wenza ukukhetha okuhle kwezidingo zakho ezithile.

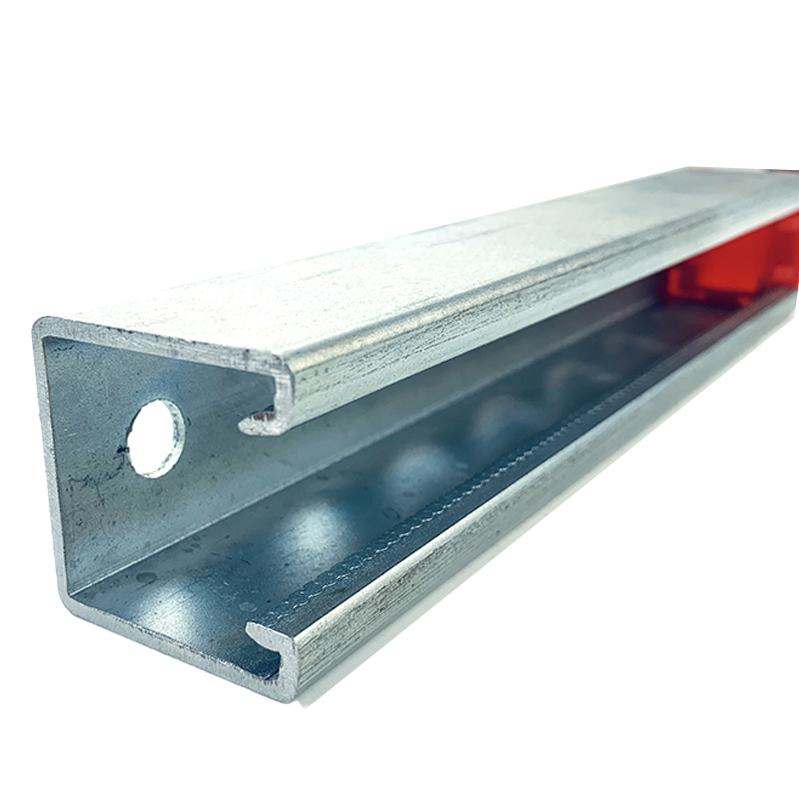

Ingxenyeiziteshi zensimbizitholakala ngokuvamile ezinhlobonhlobo zezinto zokwakha, kufaka phakathi insimbi yekhabhoni, insimbi engenasici, ne-aluminium. Indwangu ngayinye inezakhiwo zayo ezihlukile nezinzuzo, okwenza kube lula ukuthola izinhlelo ezihlukile.

Amaphrofayili ensimbi ye-Carbon ayindlela evame kakhulu futhi esetshenziswa kabanzi ngenxa yamandla abo aphezulu nokuqina. Zilungele ukusetshenziswa okuhlelekile lapho amandla ukukhathazeka okuyinhloko. Iziteshi zensimbi zekhabhoni nazo zingabizi kakhulu, zibenze ukuba kube ukukhetha okungabizi kakhulu kwamaphrojekthi wokwakha.

Iziteshi zensimbi ezingagqwali zaziwa ngokumelana kwazo kokugqwala futhi zivame ukusetshenziswa kuzinhlelo zokusebenza lapho iziteshi zivezwa khona ezindaweni ezinokhahlo noma ezintweni ezilimazayo. Baphinde bathandelwe ukubukeka kwabo okukhangayo nezidingo zokulungiswa okuphansi, kubenza babe ukukhetha okuthandwayo kwezicelo zokwakha kanye nokuhlobisa.

Iziteshi ze-AluminiumIngabe angasindi, awonakalisi futhi anesilinganiso esiphakeme sokuqina kwesisindo, okwenza balungele izinhlelo zokusebenza ezizimisele isisindo. Ngokuvamile asetshenziswa kuzinhlelo zokusebenza lapho kudingeka khona izinga eliphakeme lokuphikiswa kokugqwala noma lapho ukuncishiswa kwesisindo kuyinto ebaluleke kakhulu, njengasembonini ye-aerospace.

Kunezici eziningana okufanele zicatshangelwe lapho ukhetha isiteshi sephrofayili efanelekile yephrojekthi yakho. Isinyathelo sokuqala ukuhlola izidingo ezithile zephrojekthi, kufaka phakathi umthamo othwala umthwalo, izimo zemvelo, kanye nanoma yikuphi ukucatshangelwa okukhethekile njengokumelana nokugqwala noma ukulinganiselwa kwesisindo.

Lapho usunqume izidingo zakho zephrojekthi, ungahlola izinto ezahlukahlukene ezitholakalayo nezakhiwo zazo ukuthola inketho engcono kakhulu yezidingo zakho. Isibonelo, uma iphrojekthi yakho idinga amazinga aphezulu namandla, amaphrofayli ensimbi ye-carbon kungaba ukukhetha okufanele kakhulu. Ngakolunye uhlangothi, uma ukumelana nokugqwala kuyinto eza kuqala,insimbi engagqwalinoma i-aluminium ingaba ukukhetha okungcono.

Kubalulekile futhi ukuthi ucabangele usayizi nobukhulu besiteshi sephrofayili kanye nezinye izidingo zokwabiwa ezinjenge-welding noma maining. Udinga ukuqiniseka ukuthi isiteshi osikhethayo sinobukhulu obufanele futhi singenziwa kalula ukufeza izidingo zakho zephrojekthi ezithile.

Ngamafuphi, iziteshi zensimbi ezifakiwe ziyinto eguquguqukayo futhi ehlala isikhathi eside yokwakha. Lapho ukhetha isiteshi esifanelekile sephrojekthi yakho, kubalulekile ukubheka izinto ezahlukahlukene ezitholakalayo kanye nezinzuzo zazo zokuqinisekisa ukuthi wenza ukukhetha okuhle kwezidingo zakho ezithile. Ngokuhlola ngokucophelela izidingo zakho zephrojekthi kanye nezakhiwo zezinto ezihlukile, ungakhetha iziteshi zensimbi ezizohlinzeka ngamandla, ukuqina, kanye nokusebenza kwephrojekthi yakho edingekayo.

Isikhathi Seposi: Jan-17-2024